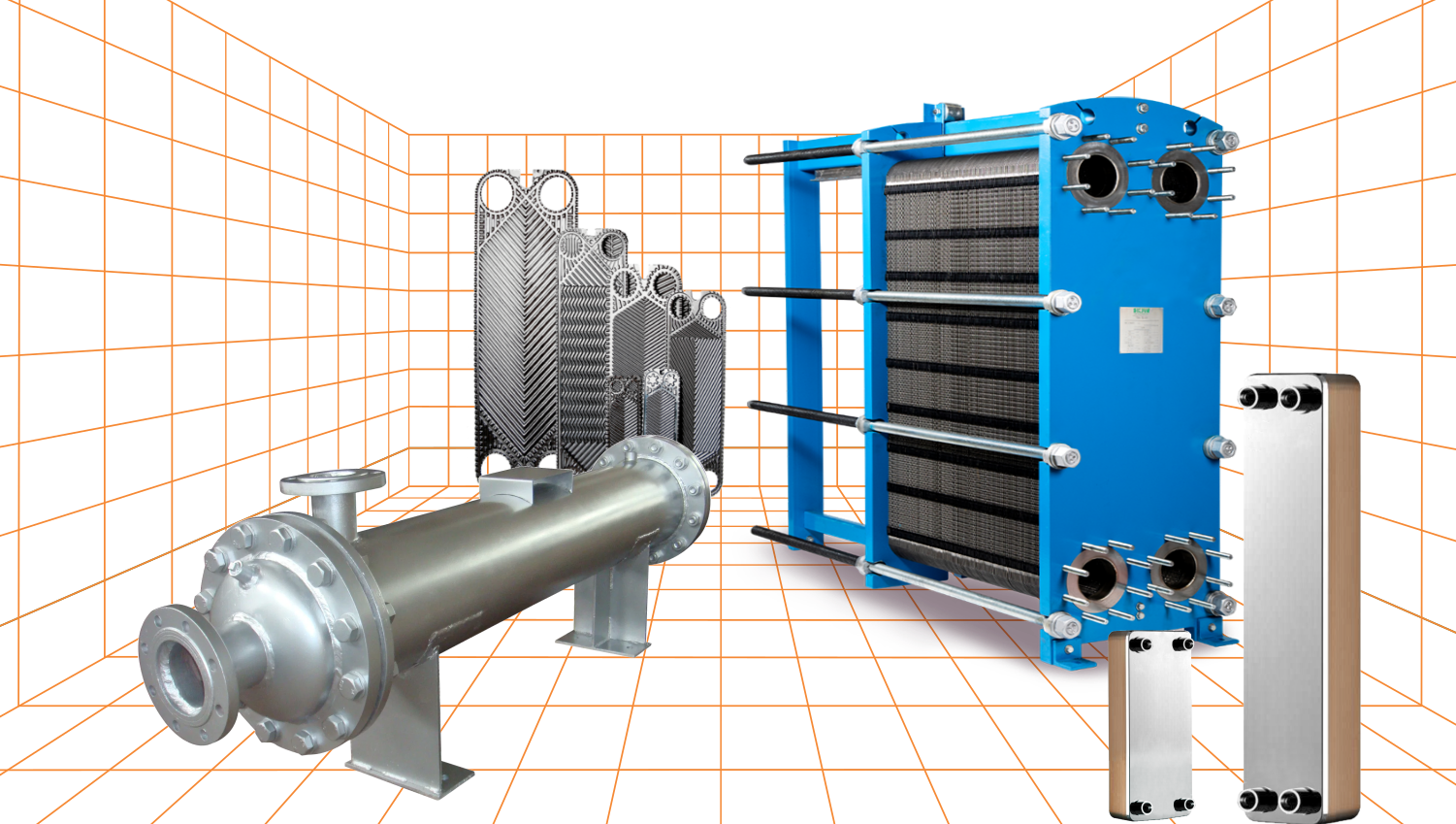

SHELL & TUBE EXCHANGERS

Shell and tube heat exchangers are essential components in industries requiring efficient heat transfer, offering robust performance and versatility. PHE-CAN excels in providing replacement parts for these critical systems, ensuring uninterrupted operation and optimal performance. With expertise in cross-referencing various manufacturers’ makes and models, PHE-CAN can supply replacement tube bundles that match the quality and dimensions of the original units, guaranteeing seamless integration and consistent thermal efficiency. Whether it’s for chemical processing, power generation, or HVAC applications, PHE-CAN’s commitment to quality and precision ensures that customers receive reliable replacement parts tailored to their specific needs, facilitating smooth operations and minimizing downtime.

PLATE & FRAME EXCHANGERS

Plate and frame heat exchangers are engineered with precision to efficiently transfer heat across various industrial processes, with each component playing a crucial role in optimizing performance. The frame provides structural integrity, securely enclosing the plates and gaskets within the assembly. Meanwhile, the plates create multiple channels for fluid flow, maximizing surface area contact and facilitating efficient heat exchange. Gaskets seal the edges of each plate, preventing fluid leakage and ensuring seamless operation. Together, these components work harmoniously to promote efficient heat transfer, making plate and frame heat exchangers indispensable assets in industries ranging from HVAC systems to food processing, where reliability and performance are paramount.

brazed Plate Exchangers

The BPHE consists of multiple thin, corrugated plates stacked and brazed together in a sandwich-like structure. These plates are typically made of stainless steel, although other materials like titanium can be used for specific applications. The plates are joined together using a brazing process, where a filler material (often copper) is heated above its melting point and distributed between the plates. This brazing creates a durable and leak-proof bond between the plates. Fluid ports are provided on the plate exchanger for the inlet and outlet of the two fluids. These ports are typically on opposite sides of the exchanger to facilitate efficient heat transfer.

“To help us provide the most accurate replacement options, please reply with the brand and frame of your Plate Heat Exchanger. We strive to provide individual replacement parts or complete packs efficiently, minimizing downtime with expedited delivery. Please fill out this form, and we will respond within 24 hours.”